Cleaning/Repair

Cleaning

Active cleans all types of radiators, charge air coolers, and oil coolers. In addition to cleaning cooling components, we also clean hydraulic tanks.

Our technicians use a variety of chemicals, equipment, and cleaning methods to clean parts internally and externally and return them to proper operating conditions.

Internal Cleaning

- Charge Air Coolers – a failed turbo will invariably dump oil into your charge air cooler, causing it to be inefficient. Active can clean your charge air cooler and remove all oil in an environmentally safe and approved manner.

- Radiators – when coolant breaks down, a harmful reaction can occur due to the mixture of metals and weak coolant. The result can range from corrosion and solder bloom in copper and brass radiators to an oily, sludge type substance in aluminum radiators. A bad head gasket can also cause oil to enter the radiator. A combination of chemicals and hot pressurized flushing can restore most radiators to proper operating condition. In extreme internal clogging situations, the radiator may need to be soaked in a vibrionic tank or dis-assembled and have the tubes individually cleaned by rodding them out.

- Oil Coolers – Contaminated oil and burnt overheated oil can cause a sludge type substance causing it to be inefficient. We install the cooler in a special tank and flush Turbo Kleen through the cooler to break down the sludge. Then we use a hot pressurized flush to remove all sludge and chemicals.

External Cleaning

Radiators, charge air coolers, and oil coolers have external air-cooling fins as part of the core assembly. The fins transfer the heat from inside of the tube and transfer it into the atmosphere. In the ordinary course of operation, fins collect dust, oil, road salt, bugs, and a variety of other contaminants, all of which reduce heat transfer. In addition, when working in off road environments, the air fins can become distorted and bent, restricting air flow. After a thorough cleaning we straighten the air fins to restore proper air flow.

Copper and Brass Radiators

Radiators must be properly cleaned before beginning the repair process.

- Cracked Tank – A cracked brass tank can generally be repaired using a special type of silver solder.

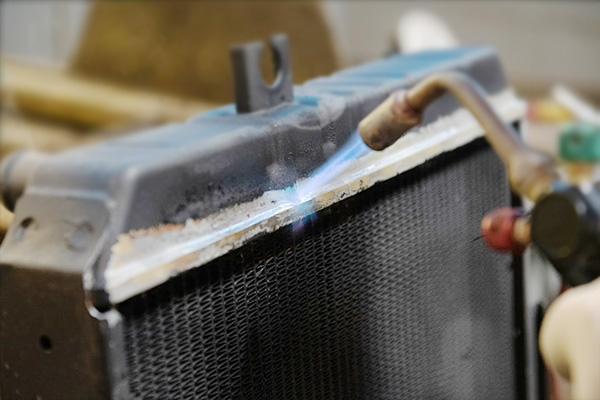

- Seam Leak – A leak in the seam between the tank and the core can generally be repaired. The technician will remove the old solder, sandblast the area and resolder.

- Core Damage – It is common for a stone or some type of debris to strike the core surface causing damage to the tubes. If the metal is in reasonably good condition, most tube damage can be repaired.

- Tube to header joint leak – Corrosion is generally the underlying cause of tube to header joint leaks. Depending on the extent of the corrosion, this type of failure may or may not be able to be repaired.

Aluminum Tank – Aluminum core radiators

- Cracked Weld – the tanks are welded to the core. A cracked weld can generally be repaired. Our technician will grind out the failure weld, prepare the area and reweld.

- Core Damage – It is common for a stone or some type of debris to strike the core surface causing damage to the tubes. If the metal is in reasonably good condition, most tube damage can be repaired.

- Core Leak – a core leak can be caused by internal corrosion or a fatigue brazed joint. This type of failure can sometimes be repaired by cutting an opening in each tank and closing off the failed tube.

Charge Air Coolers

- Broken Mounting Bracket / cracked tank; This is usually the result of worn-out rubber mounting grommets. We can make the repair by tig welding.

- Core Damage – It is common for a stone or some type of debris to strike the core surface causing damage to the tubes. If the metal is in reasonably good condition, most tube damage can be repaired.

- Cracked Tube at Header – a cracked tube is generally the result of metal fatigue. Depending on the severity, a cracked tube or tubes may be repaired by using a two-part epoxy.

Plastic Tank Aluminum Core Radiators

- Cracked Plastic Tank – A plastic tank cannot be repaired. New plastic tanks are generally not available as a stand-alone component. If a plastic tank is available, Active’s technicians can remove the old tank and install the new tank.

- Core Damage – It is common for a stone or some type of debris to strike the core surface causing damage to the tubes. If the metal is in reasonably good condition, most tube damage can be repaired.

- Cracked Tubes – when aluminum tubes are cracked the underlying cause is generally a combination of stress and metal fatigue. While a two-part epoxy can often provide a temporary repair, it is recommended that the unit be replaced.

Aluminum Oil Coolers

- Failed Tubes – Oil coolers operate under relatively high pressure. The combination of temperature, pressure, and thermal cycling can cause tubes to fail over time. This type of failure can sometimes be repaired by cutting an opening in each tank and closing off the failed tube.

- Cracked Weld – the tanks are welded to the core. A cracked weld can generally be repaired. Our technicians will grind out the failed weld, prepare the area and reweld.