Manufacturing

Active manufactures custom-size radiator cores, complete radiators, high-pressure oil coolers, high-pressure air coolers and commercial condensers. With such a variety of product lines to choose from, Active is the industry’s premier choice for heavy-duty & high-performance part needs.

Aluminum Units

Brazing: Active uses a controlled atmosphere furnace. This process allows for consistent temperature across the core which facilitates robust final joints.

Copper and Brass Units

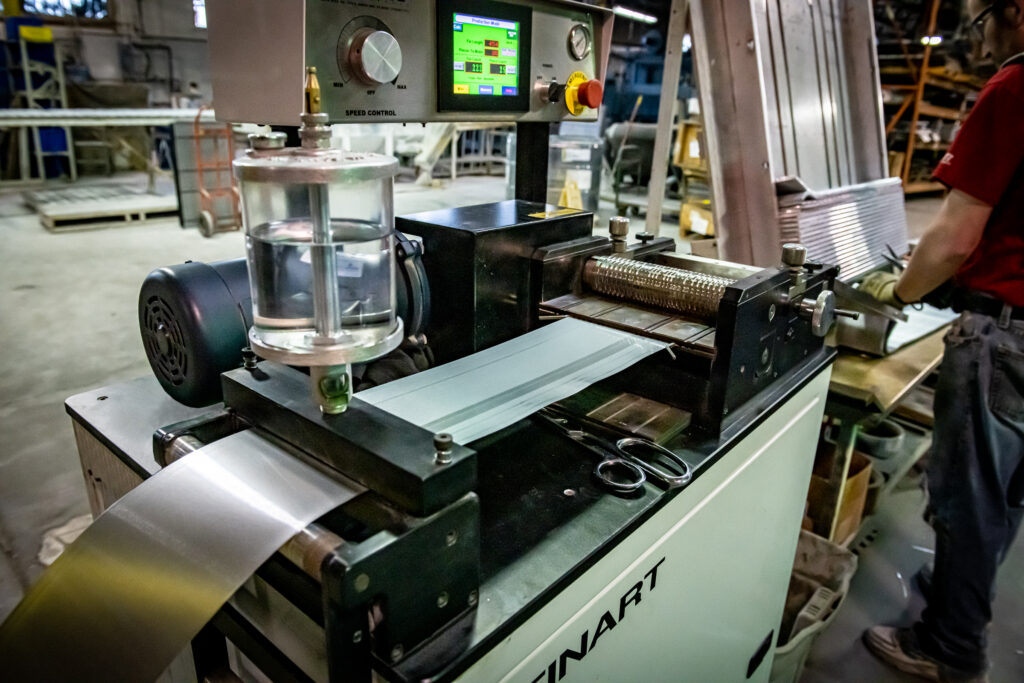

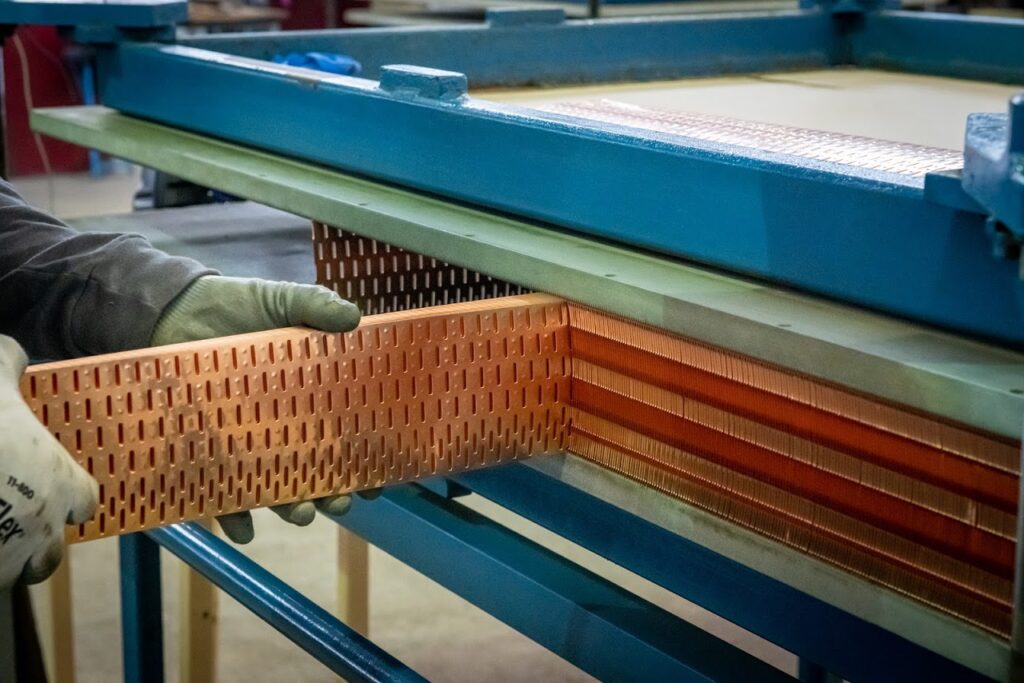

Header Production: A technician programs a CNC machine to punch a pattern of tube slots into sheet brass

Active Radiator engineers will work with companies to develop prototypes and create adaptations to existing cooling packages when needed.

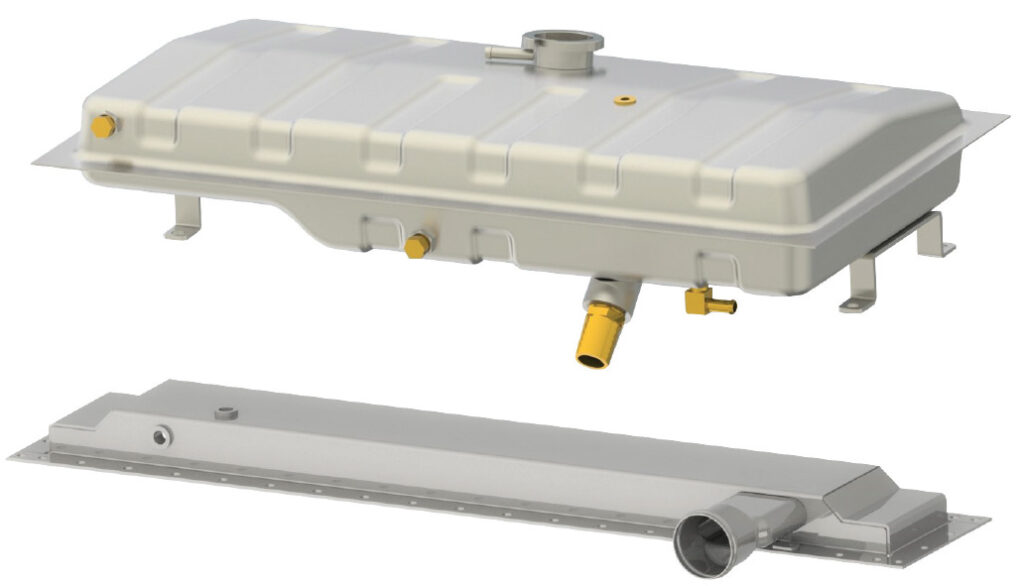

Stamped Brass Tanks

Over the years Active has manufactured over 200 complete copper/brass radiators for trucks and off-road equipment. For your convenience, Active offers die stamped Brass tanks separately.

Active’s die stamped tanks offer:

- Ribs for extra strength

- Drop seam finish

- Flanged connection openings

- Heavy gauge brass tanks

Active designs and machines all dies in-house. If you have a need for die stamped brass tanks for small quantities Active can quote for tooling, stamping and finishing.

* Hose Connections * Threaded Fittings * Mounting Studs * Filler Necks also available

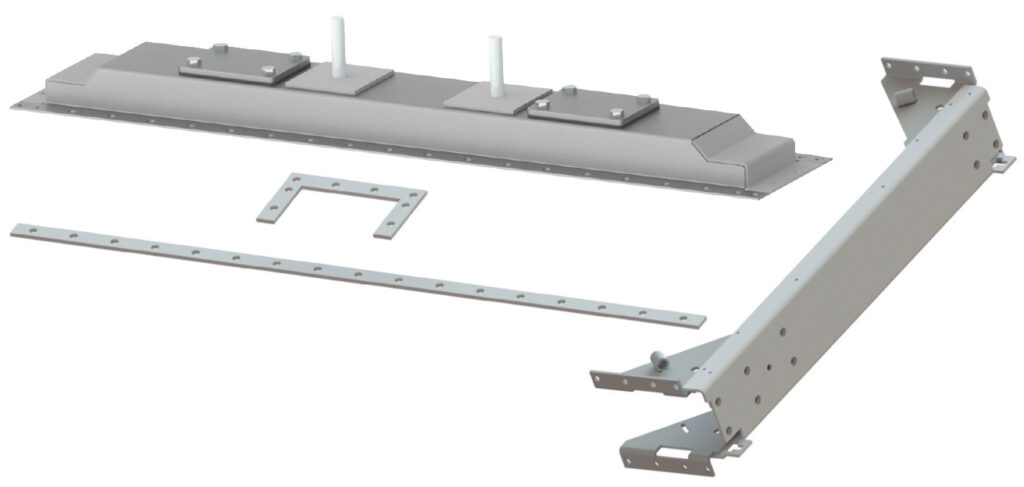

Steel Tanks and Side Frames

Active fabricates steel tanks for any application. Our tanks and side frames are the best in the industry. Every tank is manufactured to exact tolerances.

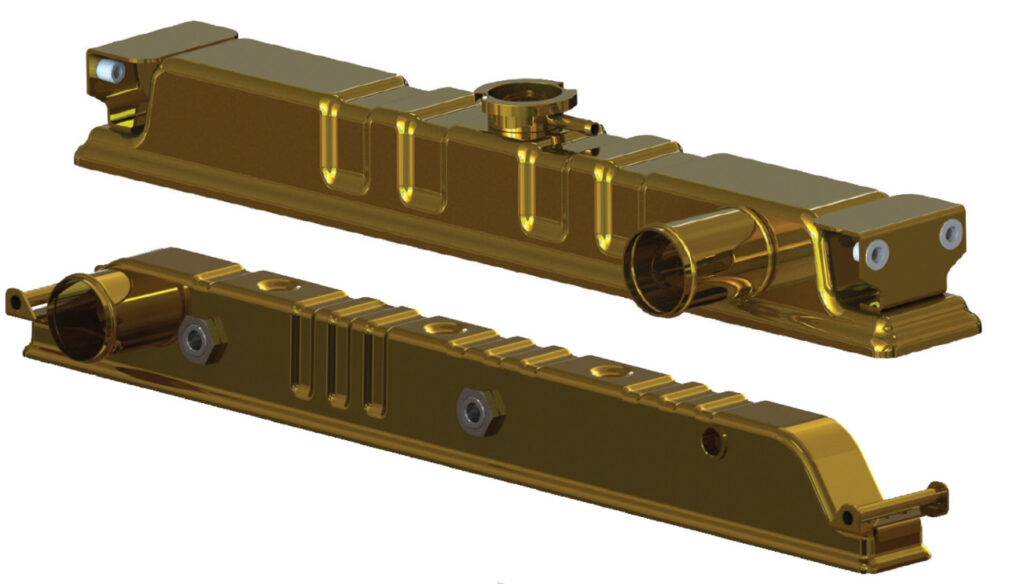

The process begins with one of our engineers preparing a 3D model in Solidworks software. That file is then sent to our fabrication department and a flat pattern is precisely cut in one of our laser cutting machines. The blank is then precisely bent in one of our CNC press brakes.

Next the part is welded, ground and tested. Most custom build tanks can be built in 1-3 days.

Stock Parts:

Active manufactures bolt style radiators for trucks, buses, and gen sets. As a result, we have tanks, frames, and bolt bars in stock for most popular applications. Your customer may need more fins per inch, fewer fins per inch, flat fin style core, dimpled tubes, more rows for additional cooling. Active offers kits for the popular Peterbilt, Kenworth, and Freightliner radiators so you can order a core from your local supplier and build your own complete.

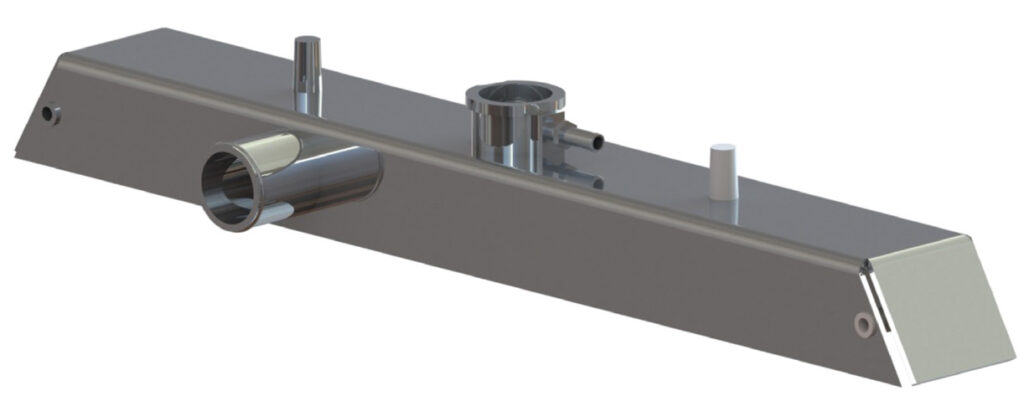

Aluminum Tanks Fabricated

Fabricated tanks are suitable for replacing both O.E. plastic tanks and O.E. aluminum tanks.

Featuring:

- 3D design for precision fit

- 3/16″ material

- Expert tig welding

Active can fabricated aluminum tanks per your requirements / single or multiple quantities.

* Hose Connections * Threaded Fittings * Mounting Studs * Filler Necks also available

Active manufactures aluminum tanks for radiators, charge air coolers, and oil coolers.

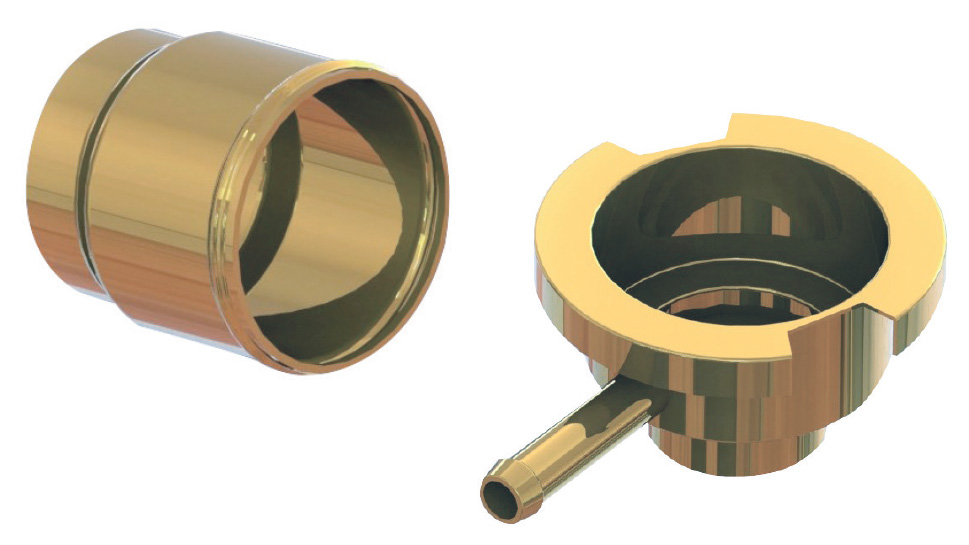

Extruded

Extruded tanks are suitable for high pressure oil coolers and bar header style radiators and charge air coolers.

Featuring:

- 3d design for precision fit

- Extruded 1/4″ material built to withstand 500psi

Custom Aluminum Expansion Tanks Also Available

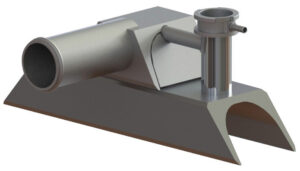

Cast Tank Radiators

Since 2010 many bus and industrial radiators come factory equipped with 5″ to 6″ wide plastic tanks. Thermal Cycling causes stress on the plastic tank. The wider the tank, the sooner it is likely to fail.

Active has designed heavy wall cast tanks for many applications. Cast tanks provided a much greater service life than plastic tanks. Active cast tanks welded onto our premium extruded tube core insure the most durable radiator in the industry.